Polyester toughener & Polyester-based alloys compatibilizer

Description

Fine-Blend® SOG-03 is a glycidyl methacrylate grafted polymer with high reactivity and low residue. The base polymer is a polyolefin elastomer. It has semitransparent pellet appearance.

SOG-03 can be completely used as substitute for EMA-co-GMA and EBA-co-GMA in PBT and PBT alloys, and also shows a better thermal stability and processability.

20wt% POE 20wt% SOG-03 20wt% EMA-co-GMA

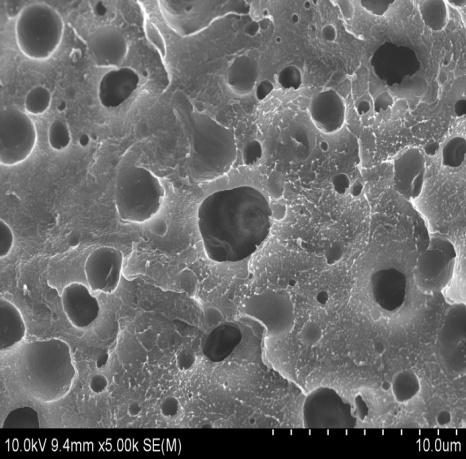

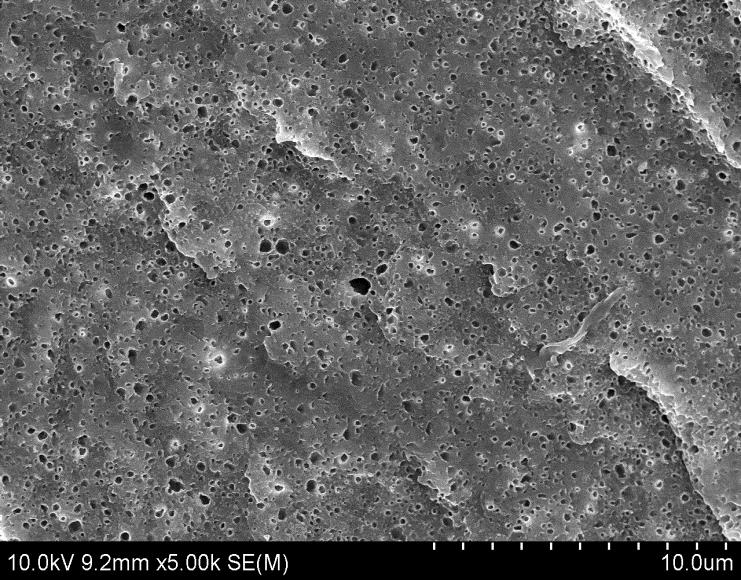

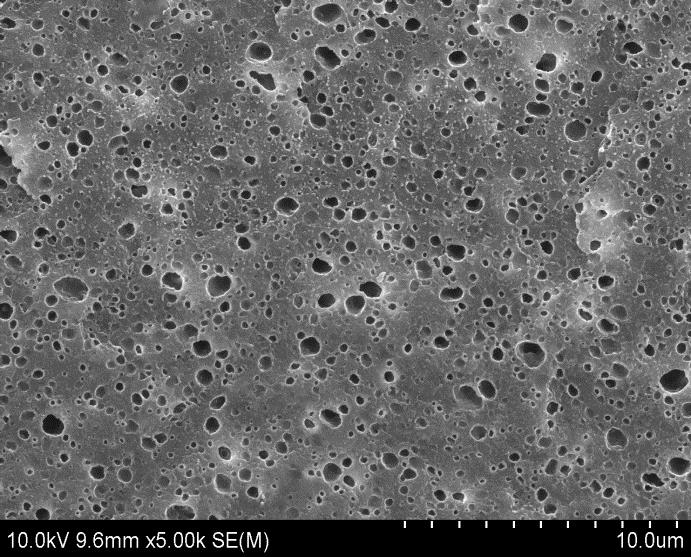

Fig The low temperature brittle fracture face of toughened PBT system with different toughner

The SEM photograph of PBT with different toughner in Fig showed that the disperse phase size were greatly reduced with the addition of SOG-03 compared with pure POE, and the disperse phase size of PBT with EMA-co-GMA is relativity smaller than that with SOG-03. This is because EMA-co-GMA has a higher GMA grafting ratio, normally at 8wt%.

Applications

Fine-Blend® SOG-03 can improve impact property, Elongation of polyester such as PBT, PET. It can be used in toughened polyester, glass fiber reinforced polyester and flame retardant polyester. It also can develop a reliable bonding strength between PC/PBT, PC/PET or PET/PO alloys.

Case 1: SOG-03 improve the heat resistance of pure toughened PBT and PBT/GF system

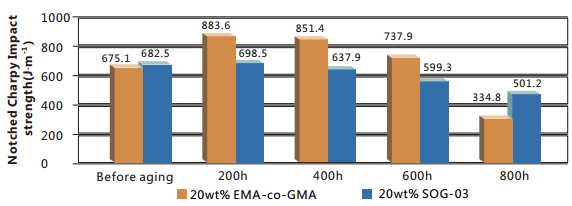

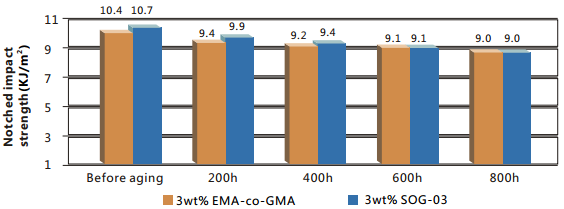

Fig 1 The influence of long term thermal ageing on impact strength of toughened PBT system

From the molecule structure of POE and EMA, POE has higher thermal stability and impact performance than EMA. As shown in Fig 1, the impact strength of pure toughened PBT system with SOG-03 after long term thermal ageing is higher than that with EMA-co-GMA, even after the thermal ageing is more than 800h.

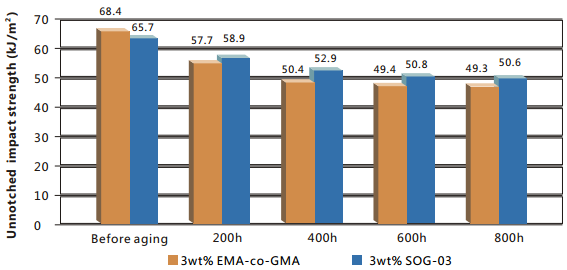

Fig 2 The influence of long term thermal ageing on the notched impact strength of PBT/GF system

Similarly, the notched impact strength (Fig 2) and unnotched impact strength (Fig 3) of PBT/GF system with EMA-co-GMA and SOG-03 after long term thermal ageing shows almost the same, even after the thermal ageing is more than 800h.

Fig 3 The influence of long term thermal ageing on the unnotched impact strength of PBT/GF system

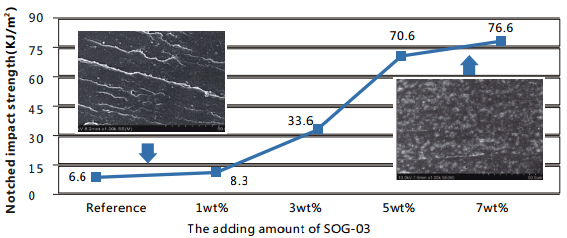

Case 2: SOG-03 improve the impact strength of PBT/GF alloy

SOG-03 also can be used as toughner in PC/PBT (70/30) alloy. As shown in Fig 4, when the addition of SOG-03 is more than 3wt%, the PC/PBT alloy reaches brittle-to-ductile transition. The impact fracture surface of super toughened PC/PBT alloy shows a typical elastomer toughening mechanism.

Fig 4 The influence of SOG-03 on the impact strength and microstructure of PC/PBT alloy

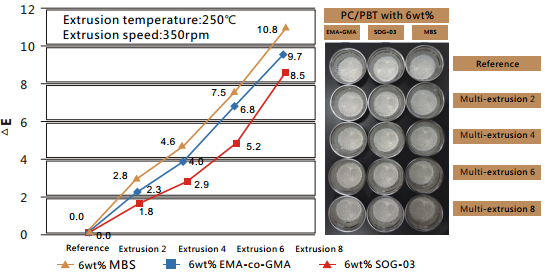

Case 3: SOG-03 improve the process ability of PC/PBT alloy

The process ability of PC/PBT alloy, such as the change of color, MFR and impact strength, with different toughner was evaluated by multi-extrusion process. As shown in Fig 5, the △E value of PC/PBT alloy with SOG-03 is the smallest after different multi-extrusion time, EMA-co-GMA take the second place, and △E value and color of PC/PBT alloy with MBS were obviously worse.

Fig 5 The △E value and color of PC/PBT alloy with different toughner after multi-extrusion process